Rotary St@dttour Bad Münder

About usGraduation Hous

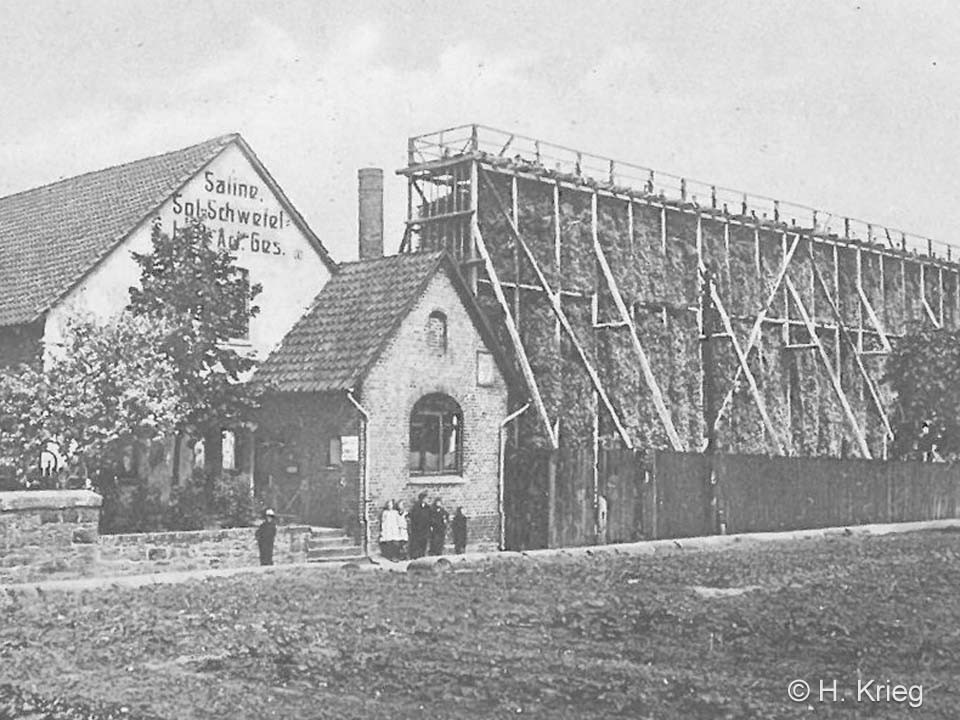

The most visible landmark building situated in the Bad Münder Kurpark (spa gardens) is the Graduation House which was reconstructed following a historical model and was sponsored by the KVV (spa and tourist office) in 1999. It is 15 meters long, 4.5 meters high and 1.8 meters wide. Graduation Houses were once used for salt production. The first document mentioning the salt extraction dates back to the year 1033. During these early years the water has been boiled from the brine source in pans, until Münder´s first Graduation House started in 1820. The Graduation House salt extraction method is based on brine rinsing down along blackthorn branches, while its salinity steadily increases ("graded"). The salt production was one of the most important economic bases of Bad Münder because salt was essential to preserve food until the invention of refrigerators. With the decommissioning of the Graduation House in 1925 Bad Münder´s nearly 1,000-year history of salt production ended. Today the salt works are only used for "therapeutic purposes". Here you can breathe properly, as the brine inhalation heals and protects the respiratory system.

more informations

In 1033 there was a sole brine extraction plant (pan) which was owned by the “Münder Salzhof” (seigniory). In 1850 however, there were already five brine extraction plants (pans) and the 1820 newly built Graduation House. The salt production in the later 19th century was in the hands of some Münder citizens. The salt pans were located outside the city in a separate former suburban called "Salz". Until 1827 these salt extraction plants were owned and managed by the Springe seigniory, subsequently, based on an exchange against agricultural space the suburb "Salz" was incorporated into the city of Münder and the salt pans were taken over by some citizens from 1827 onwards. Especially through the salt production the city gained an extraordinary economic as well as political significance.

While brine extraction plants are producing with high energy costs (charcoal or later coal) amounting to one third of its production costs, the salt Graduation House process was significantly cheaper and even better in terms of quality. Nevertheless, the increasing salt extraction from potash mining in the 20th century sets an end to salt production in Münder in 1925.

The profits from the sale of salt were for the account of their owners. 1849 salt production amounts to 1,700 tonnes in Münder. As a consequence, the city of Münder raised a salt tax which amounting to 11,348 Taler in 1849.

In addition to the five administrators 22 people worked directly for the salt pans. In addition, salt carriers, timber carters and day labour worked in salt industry. Approximately 1/6 of the produced salt was sold within the area, in particular to Hannover. Evidence shows that salt carrier transported the goods across Nienstedt to Barsinghausen and the route to Hanover led over the Deister through Wennigsen and Ronnenberg. Later, as the road from Hamelin to Hanover (begun 1764) was completed, the road crossed the Deister mountains in Steinkrug. The remaining 5/6 of the production were exported to the neighboring German territories. On the Weser, in particular from Hamelin, the "white gold" was shipped upstream and downstream.